On Friday we were given the opportunity to dye with woad in both leaf and pigment form. We were explained the complex process of extracting the dye from leaves in stages.

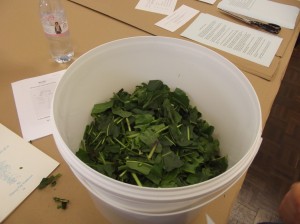

We began with the fresh woad leaves that were then torn up to release the dye. The leaves then have to be steeped in water, at roughly 90 degrees so the water is hot but not boiling. After the liquid is strained to remove the leaves leaving the pigmented water.

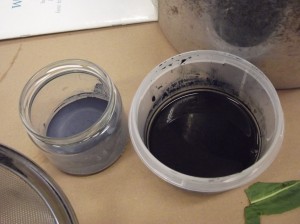

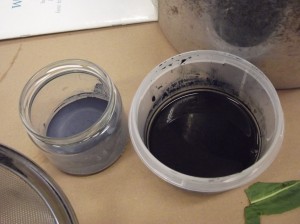

The next stage is to heat the strained liquid to a temperature that does not exceed 50 degrees, as overheating can ruin the pigmentation process. As woad is insoluble the dye itself will not attach easily to the fibres, so an alkaline has to be added to neutralise the liquid. In this case we added soda crystals. After a while the liquid had a blue foam coating the surface, and a slight yellowish tinge underneath:

Once the vat was ready to use, we carefully lowered a mixture of yarns and fabric so we could have a comparison of the effect of colour:

We left the fibres in for approximately half an hour. Meanwhile we prepared the vat using the pigment dye that had already been extracted from the leaves. This followed a similar process but cut out the preparation so the powdered pigment could be added instantly to hot water before adding the fabric. Spectralite, a chemical substance, is added with the pigment. The dying then takes roughly the same amount of time.

What was most interesting with both dying processes is the colour change the fibres underwent with oxidisation. Once taken out of the dye vat both the pigment and leaf dyed fabrics turned from a vivid florescent green to a range of blues.

Our tests with both processes showed the leaves produced a more turquoise blue, whereas the pigment delivered a deeper indigo hue.

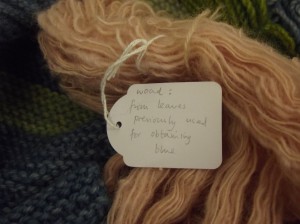

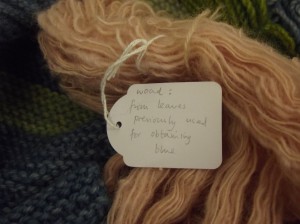

However woad is not only limited to produce blue when dying. The exhausted leaves discarded in the straining can be used to dye too. When immersed in 50 degree water as with the others, the leaves can produce a range of pink and peach tones.

Below left: an example of a pink made by using the leftover leaves. Right: A range of coloured yarns produced with woad dyes.

Although blue is not a colour obviously present in nature, it would appear this little plant has it in abundance.

A range of plants that produce blue dye.

A range of plants that produce blue dye.

Recent Comments