Cyanotyping on Fabric

The cyanotype, or blueprint, processes dates back to 1841 when it was discovered by Sir John Herschel. Although cyanotypes were originally produced on paper, they work very well on a variety of surfaces such as wood, card, leather and natural fibre fabrics. Cyanotypes are contact prints, meaning that the imagine is the same size as the object or negative that was used to create it. The white images on a Prussian blue background can range from delicate and subtle to sharp and angular.

To make the light sensitive solution, you mix ferric ammonium citrate and potassium ferricyanide. Taken from the recipe of Barbara Hewitt’s book ‘Blueprints of Fabric’, we used 30g of ferric ammonium citrate and 15g of potassium ferricyanide which we stirred into 250ml of warm water.

Mixing the potassium ferricyanide.

Mixing the ferric ammonium citrate.

Mixing the two together to create the light sensitive solution.

Fabric stretched onto a frame with the solution painted on. It is important to avoid putting it in any area where there is a lot of sunlight around. As soon as it is exposed to the light, the solution will start to react and the colour will begin to change.

Once the fabric is dry, we used the exposure cabinet to expose the solution to light. We printed our images/designs/drawings onto acetate and placed them underneath the fabric. Once exposed, the fabric is washed to remove any excess solution and the designs are are left white.

An example of the different shades of blue that can be created, depending on the fabric and the length of time the solution is exposed for.

Woad Dyeing Workshop

Yarns soaking in re-used woad. After the dye has been extracted the first time a second use of it then creates a pink colour when yarns are soaked in it.

The yarns changed colour instantly from their natural colour to the different blue tones you can achieve from Woad. Each fibre reacts diffrently, creating slight variations of blue.

Woad dying workshop

The woad plant has been used for thousands of years as a way of dying fabric and yarns blue, it also produces a light pink/beige. The blue comes from the leaves of the woad plant.

In the woad dying workshop I was part of the group using Woad pigment. Before the dying process the yarn and fabric were soaked in water, to allow the dye to take to the fibre.

We used soda crystals as a strong alkaline to allow the woad pigment to dissolve in the water. We dissolved 25gms of soda crystals in half a litre of hot water from the kettle and added 10gms of woad pigment, mixing well.

We added the dye mix to a pot of hot water and mixed in well. We then added Hydrosulfite, to help stop the colours run, to the dye bath mixing in slowly to avoid getting too much air into the bath.

After 45 minutes we slowly placed the fabric and yarns into the dye bath, carefully to avoid getting too much air in the mix.

We left them in the dye bath for about 10 minuets. When the fabric and yarns where in the water they looked a yellowy green.

When the yarns were taken out of the dye bath they were still a yellowy green colour. But when exposed to the air around it it started to change to a blue.

watch as the yarn magically changes colour

It was amazing the different amount of colours we managed to get.

When we got all the samples back, it was amazing to see the range of colours.

Woad dyeing (Friday afternoon) with 1-2-3 Fructose Vat

METHOD!

Using woad powder from woad leaves to 10gms

Measuring the fructose (sugar) to 30gms

Measuring the Calcium Hydroxide to 20gms

Checking the temperature of the water (must be 50-60 degrees)

Mixing water with the woad powder to create a paste

Mixing water and powder

Putting the paste in the hot water

Making sure all the paste is in the water

Mixing the water together

Putting the calcium hydroxide in the water

Mixing the calcium hydroxide in the water

Mixing…

Putting washed yarn in

Leave for a while…

Taking the yarn out (pull along side of the vat to get rid of the water)

Wash in clean water

Wash in clean water

Different colours can be created depending on how long the yarn is in the dye for

A dark blue

Mixture of colours

Natural dye compared to synthetic dye

Not a good vat- it has blue bubbles in it!

The collection of blues created

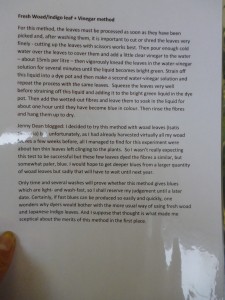

Woad Dyeing (Friday afternoon) with woad leaves and vinegar

METHOD!

Cutting woad leaves

Adding vinegar to the woad leaves

Mixing the leaves together

Straining the woad leaves

Straining the woad leaves

Strained mixture

Washed yarn

Silk- washed yarn

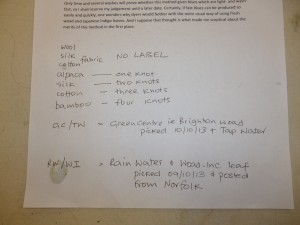

Identification of the yarn

Washed yarn- ready to put in the dye

Putting the yarns in

Yarns in the dye

WAIT ONE HOUR.

Taking the yarn out of the dye

Taking yarn out of the dye

Taking yarn out of the dye

Recent Comments