Professor Crua will be part of £1.35 million consortium project investigating Minimum Quantity Lubrication (MQL) in precision manufacturing, which is being funded by Innovate UK.

Many UK businesses continue to rely on ageing machinery that uses an excess of costly, environmentally damaging and machine degrading coolant. The upcoming green revolution will put a spotlight on machining practices at the heart of several UK industry sectors including energy, automotive and aerospace.

Instead of flooding a cutting area with coolant, MQL delivers a tiny quantity of oil to the cutting zone. This reduces the amount of coolant required by up to 99%, while recent research by University of Sheffield’s Nuclear Advanced Manufacturing Research Centre (one of the other project collaborators) has shown that MQL can reduce running costs by up to half and energy use by a fifth. It can also avoid the need to clean the component after machining, and reduce health risks to machine operators.

Professor Cyril Crua

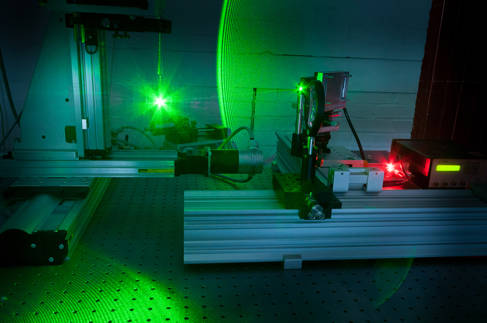

UltraMQL equipment

The Advanced Engineering Centre will help develop a cost-effective Ultrasonic Minimum Quantity Lubrication (UltraMQL) system to retrofit to existing machining equipment. This will enable small and medium enterprises (SMEs) to take advantage of previously unaffordable technologies, and upgrade for incoming regulations under green revolution and Net Zero targets.

This is part of a wide project involving research partners from all over, including international machining fluid provider Quaker Houghton, Derby-based digital visualization and immersive technology specialist Bloc Digital, the University of Sheffield’s Nuclear Advanced Manufacturing Research Centre, and precision machining specialists Kugel Rotary, who lead the project.

The three-year project builds on established minimum quantity lubricant (MQL) techniques which, instead of flooding the cutting area with coolant, deliver a tiny amount of oil to the cutting zone – typically less than a millilitre a minute. Recent research by the Nuclear AMRC has shown that MQL can reduce running costs by up to half and energy use by a fifth. It can also avoid the need to clean the component after machining, and reduce health risks to machine operators.

Professor Crua said: “The University of Brighton will develop a new high-precision lubricator, and apply laser and imaging measurement techniques to verify the spray performance against flow rate and droplet size requirements. A finer oil mist with precisely controlled droplet sizes and flow rate will deliver a much more reliable machining lubrication system. This will be achieved using ultrasonic technology, normally found in research grade atomisers, which can be precisely tuned to produce highly repeatable droplets.”

The proposed technology will create an electrostatic charge in the droplets, which will stop them coalescing and help them adhere to the workpiece.

Stuart Vere, Managing Director of Kugel Rotary Services, said: “Lubrication is a critical factor during metal cutting processes. Insufficient lubricant as well as excessive lubricant can have a detrimental effect on quality, cost and time and have an adverse impact on the environment. Just like other flexible variables such as speeds and feeds, the application of lubrication should also be optimised to ensure the best results whilst keeping overall oil contamination to a minimum.”

Leave a Reply