Neil Gershenfeld (2012) suggests a future where “[d]igital fabrication will allow individuals to design and produce tangible objects on demand, wherever and whenever they need them.” (p 43). A future where we will use personal fabrication processes to “make what you cannot buy” (ibid p49): bespoke solutions to specific needs rather than ‘off the shelf’ solutions, because, “the ‘killer app’ in digital fabrication, as in computing, is personalisation, producing products for a market of one person.” (Ibid p 46).

We are all different shapes and sizes with individual needs, tastes and appetites, therefore we want products manufactured based on our individuality. Perhaps clothes or footwear printed based on our exact measurements, because “The most compelling possibility of such a new process is customization” (Wilson, 2014, no page)

The medical industry is one field where the individuality of 3D printing solutions is central to the technology. As treatment can be specific to a specific case and again “the biggest advantage is that everything is customizable,” Markus Fromherz, (Xerox’s chief innovation officer in healthcare) as quoted by Forbes.com.

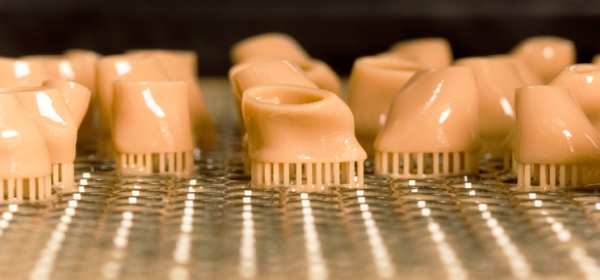

Currently 3D printing is offering personal solutions to those who can access it, afford it and know how to use it. Therefore, having an specific, individual solution can be socially exclusive to those without access to the technology, creating a new digital divide? Take as an example, the 3D printed hearing aid: CAMISHA, (‘Computer-Aided-Manufacturing-for-Individual-Shells-for-Hearing-Aids’), by Widex, a specialist hearing aid manufacturer.

“the premium sound and comfort comes at a premium price. While you can get a conventional hearing aid for a few hundred dollars, the CAMISHA produced models range from about $1,000-$3,000 per device.” (www.3ders.org, 2013, no page)

MIT believe that, “the most sustainable way to bring the deepest results of the digital revolution to developing communities is to enable them to participate in creating their own technological tools for finding solutions to their own problems.” (Mikhak et al, 2002, no page) Their solution is for communities to have Fab Labs, containing collaboratively owned digital fabrication technology, with which community groups can be self-sufficient by starting small manufacturing businesses.

Fab Labs are described as a utopian idea to the small business ideal, by Eric Smally, who says they are “a gleaming vision of a sustainable and prosperous future that also turns the clock back centuries to a time when cities were self-sufficient and people had the means to build what they needed.” (Spectrum.mit.edu, 2014, no page) Using a Fab Lab communities have the ability to create solutions to local problems rather than having products forced upon them by global businesses.

References

Gershenfeld N. (2012) How to Make Almost Anything: The Digital Fabrication Revolution Foreign Affairs Vol. 91, No. 6 http://cba.mit.edu/docs/papers/12.09.FA.pdf Accessed 12/05/14

Mikhak B, Lyon C, Gorton T, Gershenfeld N, McEnnis C & Taylor J. (2002) Fab Lab: An Alternative Model of ICT Development http://cba.mit.edu/docs/papers/02.00.mikhak.pdf

Smally E, (2014) Do-it-yourself Manufacturing, Spectrum, MIT Press, Winter 2014, http://spectrum.mit.edu/articles/do-it-yourself-manufacturing/ Accessed 12/05/14

Wilson M. (01/03/2013) Nike Vapor Laser Talon Football’s First 3D Printed Shoes http://www.fastcodesign.com/1672004/nike-vapor-laser-talon-football-s-first-3-d-printed-shoes Accessed 12/05/14

http://www.3ders.org/articles/20130103-3d-printing-helps-develop-the-world-smallest-hearing-aid.html 03/01/2013, Accessed 12/05/14

http://www.forbes.com/sites/xerox/2013/08/22/3-ways-3-d-printing-could-revolutionize-healthcare/ Accessed 12/05/14