Current Project – Work in Progress! Increasing the accessibility of sustainable shaving to the majority of users by modifying an existing product; a Gillette or a Wilkinson Sword razor. 3 Week Project as part of the Other Today Studio at the University of Brighton 2nd year BSc Identifying and Modifying an Existing Product Starting with […]

Author: Luke Kelly

Tyvek Tool Caddy – Waste Stream Product

The tool caddy stores worksite hand tools using waste Tyvek sheets commonly found on construction sites. 3 Week Project as part of the Other Today Studio at University of Brighton 2nd Product Design What have I done? My project began with an interest in using a textile as the sheet material. Early on I focused […]

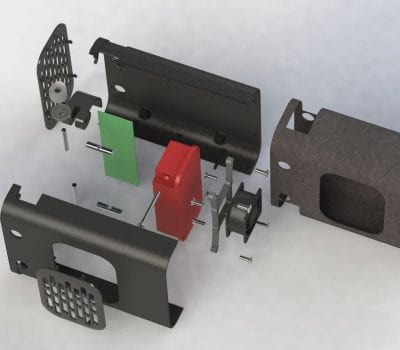

DP403 Summary

3 month project based on consumer heating. This was a fun project and some is shown below Full report and Appendix. Rendered Exploded View

DP402 Summary

This project was based around moving homes constantly. Our aim was to produce collapsible furniture that could be easily adapted to everyday life and small spaces that students and the like would normally have to live in.

DP401 Summary

A series of week long based projects each on Form (Mouse), Surface (Tiles), Proportions (Turning) and Detail (Spatula) Mouse Tiles Turning Spatula Exhibition

A-Level DIY Multi Tool

This is some of the work completed for my A-level Multi tool Project in 2017/18. Full project available here I have included most of the manufacturing pages which show thought processes and the various methods of manufacture that took place.

Land Rover Project

Various modifications and improvements made to my Land Rover either in progress or completed. Summer 2018 Swapping Springs for the front of the Land Rover. The previous owner put the wrong springs on each side when he restored the vehicle, causing the vehicle to lean to one side as the springs are sided. The springs […]

Arduino – Week 4 – Robot

The final week task was to program a robot which would move by itself and avoid objects Unfortunately this wasn’t completed due to time constraints, although most of the code for the movements was completed and fully working The board was attached to the chassis with metal standoff – which did short the board out […]

Arduino – Week 3 – Displays and Ultrasonic sensors

Arduino LCD Displays Wire up the arduino using these following instructions VCC (Red) to 5V Ground/GND (Black) to GND SDA (Blue) to A4 SCL (Yellow) to A5 The code used was downloaded adn the library installed in the specific location. Ensure that the LCD drivers are included in the same folder #include <Wire.h> // Comes […]

Arduino – Week 2 – Stepper Motors

What is a stepper motor? A stepper motor uses opposing electromagnets to create rotation. The different number of steps are determined by the number of poles on each the stator and the rotor. There are several different types of stepper motor, depending on the use case and the size that is required. The main types […]

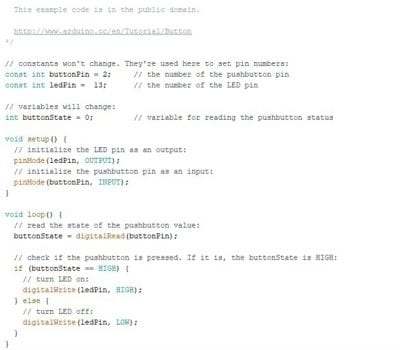

Arduino – Week 1 – Software Notes

Pulse Width Modulation Using ‘unsigned char’ to replace values > ‘unsigned char’ allows you to control all of the same variables in a sketch by only changing one value unsigned char DelayTime = 255; unsigned char LEDoutput = 2; // the setup function runs once when you press reset or power the board […]

Week 8 – Fusion 360 CAM for mould-making and casting

Design Rules for CNC/casting Most important is to know your cutter shape and size. Any features have to be designed in accordance to the diameter of the cutter as this will restrict how far and deep the slots between features can be. Try and keep the cutter as big as possible as it will reduce […]

Week 7 – 3D scanning and printing

3d Scanning can be done in multiple ways and at multiple price points, either with handheld scanner for an iPad all the way up to full systems, e.g for car manufactures to scan clay cars. They also have different degrees of accuracy, with hand held scanners being less expensive they will also produce less detailed […]

Week 6 – Embedded programmer

The task this week was to program the board that we made using the CNC router. There are several levels to this week, some being ‘simple’ and some being advanced. The main goal was to upload some sort of program to our Echo Hello World Plus board and ensure that it completed the function that […]

Week 5 : Electronics Design

The task this week was to create the schematic, board layout and then mill the simple LED circuit board. Autodesk Eagle is the circuit-board software that we used > Installing it was relatively easy as it was just a simple installation but to get the correct components for the FAB LAB, downloading the library of […]

Week 4 : Electronic Production

Surface mount components are very common and are what the majority of manufacturers will use due to the smaller size, compared to through components. It seems fairly easy to use them, although the mounting of these components, via soldering is vastly different to through hole components. Through hole components have the obvious advantage of being […]

Week 3 : Laser cutter: computer-controlled cutting (CNC)

Task: Produce a press fit kit (accounting for kerf) using the laser cutter Making the Design The main aim is to use parametric design software to ‘simplify the process’. Being able to edit the sketch automatically by adding parameters and using these to dimension the sketch instead of manually changing them. First step was to […]

Parameters in Fusion 360

Parameters are used to define a sketch and easily edit it later on. It is basically using a smart dimension but that can be used over and over again. Parameter is located under modify E.g. a thickness for a slot would be material_thickness – (2*laser_cutter_kerf) + addition – subtraction % floating point modulo * multiplication / division ^ power ( following BIDMAS […]

Week 2 : CAD, Manufacturing and Modelling

The task this week was to make on Fusion 360 a version of our tile, render it and display it as a pattern of 9. Method Start new sketch > Draw 100 x 100 mm square using corner to corner rectangle tool > Exit sketch Extrude 13mm with a taper of 4 degrees (minimum required […]

Solidworks Notes

Help Menu > Solidworks tutorials is a good place to go if stuck GrabCAD is an online source of downloadable CAD files which can help you to learn how they made a model – with the feature tree you can see every step of them making the model I have used Lynda.com to start learning […]

Dice making Fusion 360

Making the dice is about learning Fusion 360 and using as many different techniques as possible My original method is as follows: Sketch 10×10 square > Extrude up 10mm > draw on dots by either using the pattern tool and deleting the extras or using the construction line at a diagonal and making equal circles […]

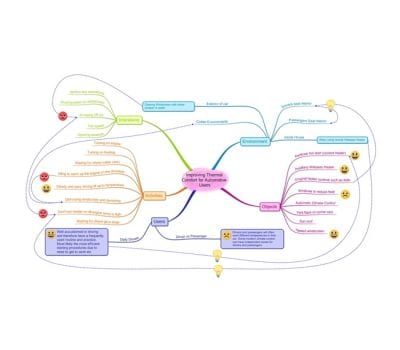

Mind Mapping

I decided to use a mind map for the DP403 projects research analysis and wanted to record the process for future reference. Looking online there are several good mind mapping software but due to the ability to have a free trial I went with iMindMap. The first step is to choose a theme similar to […]

Fusion 360 Notes

Everything must have a dimension to lock it in place- blue lines indicate something that hasn’t been dimensioned Coincident – Where two points join together Concentric – Have the centre in the same location, share the same centre point. Co-linear – Same angle of a line for example Co-radial – same radius for the same […]

Week 1: Introduction, websites and project management

This week task was to create our own web page by either using edublogs or another website software. I chose to go with edublogs as they are supported by the university and therefore would have support available. Choosing a theme was difficult and I went through several to find the correct one, eventually choosing ‘Weather’. […]