Proposed Materials

Silicon

The wristband can be manufactured using silicon

Advantages:

- Able to come in a variety of colors to match the user’s preferences

- Has a good low and high-temperature resistance

High resistance to corrosion and water

- Comfortable to touch and wear

- Not toxic and has no odor making it not harmful for human skin

- Has a good tactile sensation, and strong plasticity

- Good tensile strength and wearproof

- Difficult to age and color fading

- Very durable and easy to clean

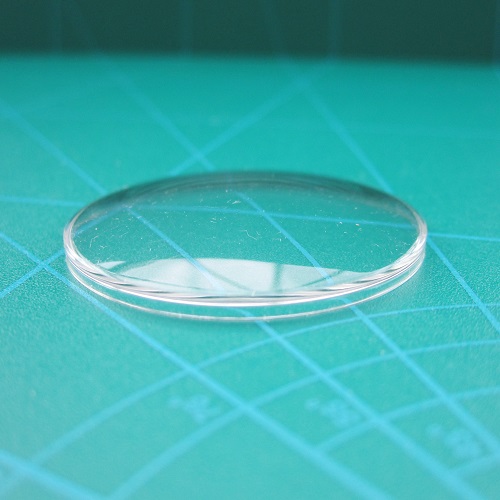

Acrylic Crystal

The pendant body can be manufactured from Acrylic crystal

- Resistant to day to day knocks around the house

- More cost-effective crystal on the market

- Not easily shattered

- Provides valuable protection for pendant face

Electrical Components

- Lithium-Ion Polymer Battery

- Vibrating Mini Motor Disc

- MAX30102 High-Sensitivity Pulse Oximeter and Heart-Rate Sensor for Wearable Health

- Maxim Integrated MAXREFDES117

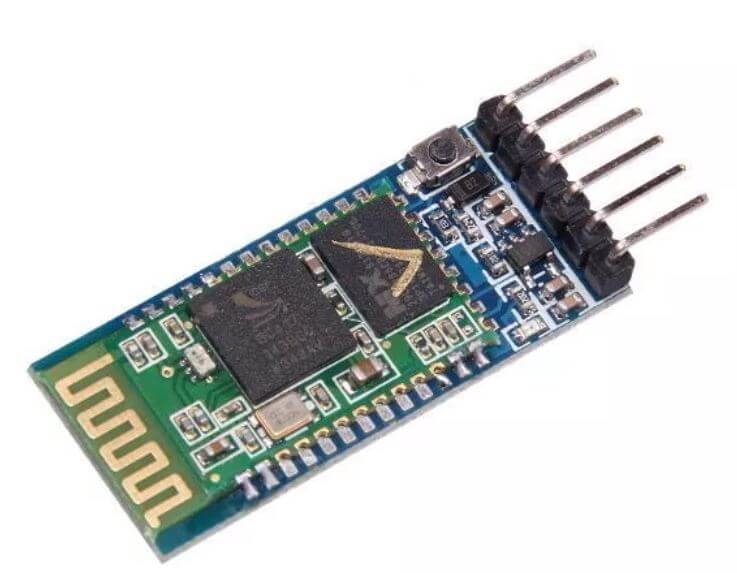

- HC-05 Bluetooth Module

Proposed Manufacturing Processes

Injection Moulding

Firstly the mold of the wristband strap is created as a 3D drawing

The 3D drawing is then made into a silicon mold

The mold is then used for injection molding

Advantages:

- Able to achieve detailed features and complex geometry

- Has very high efficiency

- Enhanced strength

- Able to have the flexibility and use multiple plastics and different colors

- Reduced waste

- Produced identical good consistency products

BOM (Bill of Materials)

As seen from the bill of materials, the cost for materials of one wearable device would total to $75.12. When taking into consideration the cost of manufacture, the total would amount to around $180 per item. As this can be quite expensive, the customer has the option to forgo purchasing the wearable device and instead have the capability of using the heartbeat-like vibration being simulated on their personal phone. However, this is limiting as the device would have to be in physical contact with the phone at the time of the panic attack for it to have an effect. Also, the phone won’t be able to automatically sense the user’s increase in heart rate so the vibration feature would have to be turned on manually by the user which is not always ideal for them in an anxious state.

Exploded View of Wearable Device

The above diagram shows the different components which are included in the wearable device as well as how all the components would fit in the housing together. The pendant which includes the optical heart-rate sensor and the vibrating sensor is a detachable piece. The components are housed together and then covered with another base where above this the 3D personal design the user has selected can be laced and then covered with the top clear enclosure. The pendant can easily be fitted into the designated opening on the silicon strap or be used as a pendant for a necklace by attaching it to chain with the hooks on the pendant.