Contents

Introduction

This module involves working in a group to produce a system which removes plastics and foreign materials from the ocean.

For this project, I have participated in writing the context, need and functions, background research, writing system requirements and SE architecture (which was later added to by another member), producing a concept, writing some Ethical issues, participating in creating a MoSCoW, producing a final design, making a CAD model for the final design, engineering drawings, an assembly drawing, writing a section on validation and collaborating with the rest of the team to produce a presentation about our design. I have also kept a record of the meetings and actions.

Context

In today’s waters lie trillions of plastics and foreign materials, these include bottles, bags, microplastics, macro plastics and many more. As a result of these plastics and foreign materials being thrown into the ocean sea life is being affected and greatly endangered from either being caught up in the waste or consuming these plastics and foreign materials. Not only are the animals being endangered, but the whole ecosystem is also being affected because of those animals dying. Due to this problem, many people are finding ways of reducing the amount of plastic and foreign materials within the ocean.

For this project we will be producing a system which will help to remove these plastics and foreign materials from the ocean

Meetings and Actions

18/02/2022 Present: All Location: Teams

Talked about project. Decided on East Garbage Patch in California as our area for our design. Discussed potential ideas for designs. Agreed on having some sort of mothership which could be used as a storage system for foreign materials once collected. Talked about potential use for AI/Machine Learning to operate systems.

Actions:

- Each member produces a concept for the next meeting

- Decision matrix can then be made to determine which idea we can work on

- Internal and external Interfaces

- User and System Requirements to be made, considering the area, constraints, and context

Other Actions

- List of stakeholders and a table of scenarios

- Architecture – need to be logical

- Key functions and functions hierarchy

25/02/2022 Location: in-person

Presented the work which we had done, some concepts were done as was asked from the last meeting. Mainly discussed the concepts and discussed the next steps. There are still some tasks that need to be done which we either haven’t started or completed.

Actions:

- Gantt Chart needs to be produced (Anthony)

- Architecture requirements (Mohammed)

- Internal and external interfaces

- Context

- Initial concepts (1 per person)

04/03/2022 Location: in-person

Today we gathered and presented our current work for this module, we need to ‘flesh-out’ and improve some areas, such as our user and system requirements and our justification of subsystems.

Actions:

- Decision matrix needs to be made to determine which design to take forward

- Human factors (HFI)

- Safety:

- Risk assessment

- Risk issues

- Make improvements to:

- User requirements

- System requirements

- Justification of subsystems

08/03/2022 Present: All Location: Teams

We discussed our roles and responsibilities and allocated lead roles, Team Leader is Scott, Project Planning lead is Anthony, CAD and Simulations lead is Mohamed, PDS lead is will and Health and safety lead is Ajin.

We have agreed that Scott will write a list of what needs to be done, then we will meet on Friday to perhaps produce a final drawing, decision matrix and perhaps a CAD model.

We discussed the decision matrix and what would be used to decide the best concept – cost, need and requirements met, economic impact, material, workability, availability, environmental impact, ecosystem impact

User requirements were discussed, who is the user, user of the system, if it’s sailed then we need lifeboats, bridges, AI drones and Remote-controlled motherships would reduce risk. Operation limits such as weather – sensors to identify conditions.

Actions

Scott – produce a list of what needs to be done for Friday

- User requirements

- System requirements

- Stakeholders

- Risk assessment

- Human Factors (HFI)

- Decision matrix

- Final drawing and CAD

11/03/2022

- User Requirements need to be written up

- System Requirements need to be explored more

- SE Architecture could be expanded upon, maybe have more subsystems.

- Justification of Subsystems – use this alongside the system and user requirements

- Decision Matrix to decide what concept to push forward

- Ethical Issues and Environmental Issues

- Final Drawing with CAD Models

- Costings – the potential cost of different parts and components, manufacturing, labour

- Risk Assessments and Safety

- Human Factors (HFI)

Scott’s Tasks

- Ethical Issues

Anthony’s Tasks

- Project Planning, Meeting and Actions, Legislations & Laws

Will’s Tasks

- User requirements, system requirements and SE architecture, MoSCoW Decision Matrix (Tuesday – Guide Team)

Mohamed’s Tasks

- Environmental Issues

Ajin’s Tasks

- Risk Assessment and Safety

- Human Factors (HFI)

Tuesday

Decision Matrix, Final Drawing. CAD (potentially)

Friday

User requirements, system requirements, environmental issues and ethical issues SHOULD BE COMPLETED

Background Research

This article explains plastic pollution, plastic leaks and provides numerous solutions for removing plastic from the ocean.

One such example is the sand filter. This is where ‘sand is piled on a sheet of fine mesh stretched between two long poles, and the mesh catches plastic and other foreign materials’

Another example is the use of a Vacuum. In the article they mention that the plastic would be vacuumed into a tank which would then filter out the plastic.

https://www.clearbluesea.org/meet-fred/

This organisation shows their own solution, this is FRED, it is powered by solar panels and doesn’t emit any pollution.

It moves at 2 knots and collects plastic and other foreign materials from the ocean via a conveyor belt.

It has ‘pingers’ that alert marine wildlife when it is nearby.

It unloads onto a mothership where the devices are controlled, and the plastic is then taken away to be reused and recycled.

This study talks about marine debris pulverization. The study looks at improving marine debris recycling and talks about how pulverization could achieve this. This concept is backed up with equations and formulas.

Need

A system which efficiently collects plastics and other foreign materials from the surface of the ocean at the eastern side of the great pacific garbage patch

Functions

- The system needs to collect plastic and foreign materials from the ocean

- The system needs to be able to hold plastic and foreign materials

- The system needs to be able to empty the waste and foreign materials

Architecture

System Requirements

| System Requirements |

| Performance |

| Cover a 10Km Area of earth’s oceans |

| Remove Micro Plastics at minimum |

| Contain a defined amount of collected detritus back to mainland. |

| Function in ALL defined operational weather conditions |

| Autonomous or Semi-autonomous. |

| Collect a minimum of 2 metric ton of material. |

| Operate on renewable Fuel source (e.g. Solar, wind, etc.) |

| The system must be operating (battery life, fuel, etc.) for more than 1 hour |

| The system needs an entry point that needs to be bigger than a 19.6 once bottle and no bigger than a 1-liter bottle |

| The system must be able to collect and unload plastics and foreign materials |

| The system needs to prevent water ingress |

| Manufacturing |

| Minimise Environmental Impact for fabrication. |

| Repurposing of large vessels e.g. Cargo ships |

| Materials locally sourced |

| Disposal |

| Process Waste at sea |

| Compress Plastics for more storage capacity |

| Disposing waste appropriately at port |

| Self-recycling on ship |

| Standards and Legislations |

| Adhere to all appropriate Californian recycling Legislation |

| Energy Storage regulations – PC |

| The system needs to move at a maximum speed of 15 knots |

| MARPOL Annex V – Garbage management |

| Desirables |

| The system should have lights if it should be used at night, in dark areas or underwater |

| The system should discourage animals from coming close to it |

| Hydrogen Fuel |

| Time restrictions and Deadlines |

| Have fully developed Presentation prepared by XX may |

| Have completed all design related tasks by XX may |

Concept

This design uses a vacuum which pulls plastics and foreign materials through to a ‘main chamber’. There is a filter at the back of the chamber so that water can exit the chamber and leave just the plastic and foreign materials. The plastic and foreign materials then drop into a net or a bag which expands depending on the amount of plastic or foreign material it has collected.

This design would float on the surface and focus on collecting surface plastics and foreign materials; however, it has the possibility for collecting underwater plastics and foreign materials. This could be achieved through an extendable vacuum tube. This could also collect microplastics if there was an expandable bag rather than a net.

We could use machine learning to teach the system to distinguish what is a plastic or foreign material and what is not. https://teachablemachine.withgoogle.com/train

Ethical Issues

- Those who operate boat/system require a place of rest if they are going to be out at sea for longer than a day

- Those who operate boat/system need training to control the system properly and with minimal risk

- Disposal of the collected plastics and foreign materials – if we dispose of them incorrectly then we could end up throwing them back into the ocean, furthermore, if we dispose of them incorrectly then we could be causing more damage.

- We need to make sure that we aren’t harming marine life – we could be breaking laws by harming them

- Boating laws need to be considered – again we could be breaking laws by sailing in certain areas

- https://www.sailing.org/tools/documents/2019CodeofEthicsPostMidYear-[25097].pdf World sailing code of ethics needs to be followed

- Safeguarding

- Lifeboats and other safety equipment is required on the boat to either prevent risks or to keep people safe when a hazard occurs

- Anyone manufacturing the system/device/boat should be trained to remain as safe as possible

- Anyone manufacturing should have safety equipment

Deciding on an idea

The group decided on using a MoSCoW to decide our final design, we decided that we would choose the concept which came out with the highest score and then we would see what system requirements were missing from the design and then try to add those requirements for the final concept.

Each system requirement was categorized into Must, Should, Could and Would. The musts are necessary for the product to succeed, the should are recommended to have, the could are optional and would are least likely to have.

For this activity we had to see what system requirements we thought our concept fulfilled. This is how mine scored against the requirements:

The groups decision was another concept which had fulfilled 24 out of the 27.

Final Design Concept Drawings

After choosing the concept to take forward I was tasked with producing a final concept drawing.

This is the first attempt at the final drawing, here I tried adding some systems, one of which is to discourage animals (the system requirement: The system should discourage animals from coming close to it. Can be achieved with this)

When presenting this drawing the group gave some feedback, saying that there should be a magnet so that a crane can pick it up and that it should have a way of discouraging birds as well as sea life.

This is the second design, I have added the magnet and I also added a structure to hold the drone above the water, this was so the water wouldn’t go through the filter during operation.

This is the second design again, this has been slightly adjusted for the initial second design. After this I went on to produce a digital version of this concept.

Here is the final concept drawing which has been recreated using the software Krita. I chose to create a digital version as I would be able to produce a cleaner design as well as providing a neater presentation of the concept. I was also able to give proper shading and colouring to the concept.

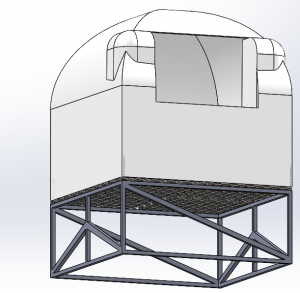

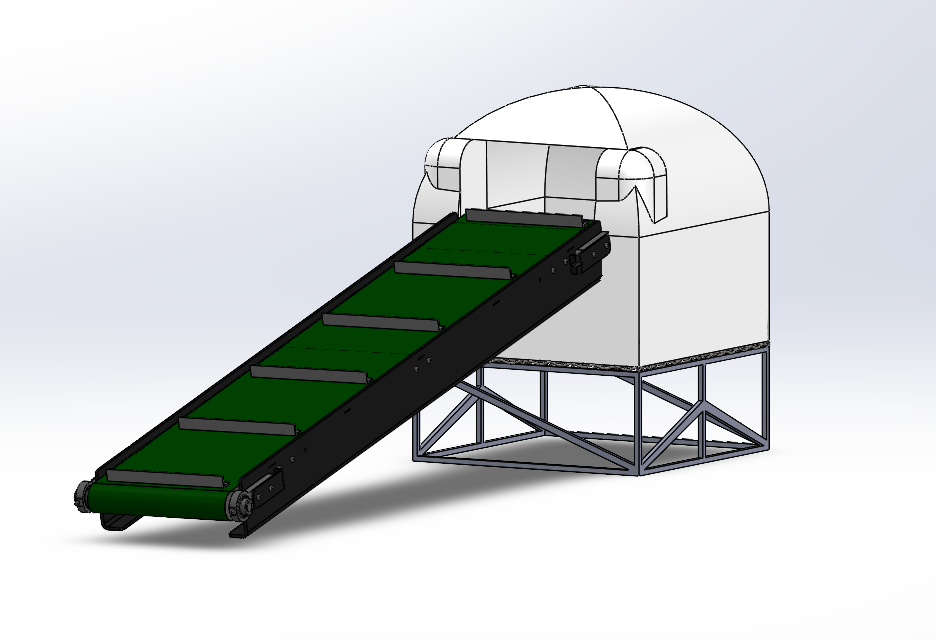

CAD Model

From the digital concept I produced a CAD model, this model includes the main bin component of the system and the float structure component (both made from scratch by myself). As well as a mesh filter and a conveyor belt (made by someone else and obtained via GrabCAD).

The mesh filter was produced by Ade Amaludin and was uploaded January 4th 2022

The conveyor belt was produced by Гонтар Петро and was uploaded April 23rd 2022

This this the design without the conveyor belt attached. In between the bin and the float structure is the mesh filter. The conveyor belt is attached to the sides of the entrance of the bin to allow for collected foreign materials to be scooped into the bin.

DOWNLOAD ZIP FILE: PRADS Assembly

Engineering Drawings

A couple engineering drawings were produced after creating the CAD Model. These are of the main bin component and the float structure.

Assembly Drawings

An assembly drawing was also produced to tell you how the different components interact and combine. There were 4 meshes used to cover the full size of the bin.

Mathematics

Here are my contributions to the mathematics of the project. I originally calculated these but they were later adjusted by another member. I found the maximum mass, the buoyancy force, the mass of plastic and the conveyor belt speed.

Validation

The groups design involves repurposing a cargo ship which acts as a central storage and home for the drones to return to. Because of this I researched into validating the boat.

CFR (Council of Foreign Relations)

Ventilation (33 CFR 175/183, 46 CFR 25)

Fire Extinguishers (46 CFR 25)

Visual Distress Signals (33 CFR 175.101) – You need approved distress signals by US coast guard. Electric distress light and orange flag required.

Life Jackets (33 CFR 175)

Registration (33 CFR 173) and Documentation (46 CFR 67) – All undocumented vessels equipped with propulsion machinery must be registered in the state of principal use

https://www.uscgboating.org/images/420.PDF

Presentation

After completing these tasks the group compiled all the work onto one PowerPoint and we presented our work to other groups that were doing the same module, as well as the teachers supporting the module.

Click on image to DOWNLOAD or Click the PDF link

Recording of the Presentation

Here is a 3 part recording of the presentation. I spoke about the stakeholders and functions, a concept, the final concept drawing, digital concept, CAD model, engineering drawings, assembly drawing, the mathematics, validation and I presented the references.

Compressing these videos

At first I had decided to re-record the presentation, this was to remove the people who had their cameras on. I decided to remove them due to privacy reasons and If anyone didn’t want to be in the video (all of my team consented to uploading the video onto my website). I used a free software called Loom, which allows you to record your screen and audio. It also provides you with your own workspace to edit the recording. https://www.loom.com/

After recording the video I downloaded it and from here I had to compress the video. The video was 400mb and this website can only upload 50mb files.

I used a couple websites to do this:

https://clideo.com/compress-video

https://www.freeconvert.com/video-compressor

I found that Clideo.com was the easier website to use for this, it was also the fastest and I didn’t come across any issues here. Unfortunately when compressing the file it only compressed to 200mb, I tried to compress the file again using the same website but that doesn’t work. So I used the other website, going back and forth and I eventually reduced the file to 70mb.

At this point I was unable to compress the file anymore, this was because the websites had hit their limits. There were some website which got the file below 50mb, however, the video quality was very poor and it was barely visible.

From the 70mb I used Hitfilms XP to split the video into 3 parts, then I compressed those parts (because the file size when up) and then I was able to upload the videos.